Frequently Asked Questions

What is the manufacture or certification date of a cylinder?

All cylinders have a manufacture date. Recertified cylinders also have a certification date. The most recent date on the cylinder is the currently active date.

The most important date to know when purchasing a cylinder is when the cylinder was last recertified (recertification means that all DOT/TC requirements for that cylinder have been met).

The U.S. Department of Transportation (DOT) requires that most portable CO2 cylinders be recertified every five years. Nitrogen and other high pressure inert gas cylinders generally have a 10 year recertification requirement (although there are exceptions). Certification must be performed by a DOT-licensed facility.

The date of the last recertification is the 8 digits stamped across the neck of the tank. The first two (which are larger) are the month, and the final two are the year in which the tank was tested. The four smaller numbers in the middle is the DOT registration number of the recertification facility.

Please see the individual product description for specific details on certification test dates.

What are the exact dimensions of steel cylinders?

Steel cylinders have dimensional variations even between the same size cylinders. Depending on the manufacturer, the cylinder’s dimensions may vary a couple of inches. We give an approximate height and width of the largest typical dimensions.

Will this cylinder work for my application?

With so many uses for gas cylinders and components, plus the dangers of improper use, we can’t verify or confirm you’re purchasing the right items. It’s your responsibility to specify and purchase the correct item(s) for your application, and to use them safely and appropriately.

Please make certain that you are purchasing the right item for your intended use before you buy.

Steel versus aluminum cylinders

Steel cylinders are more economical but significantly heavier than aluminum. Aluminum is more rust- and corrosion-resistant than steel, which is important for wet gases and in humid or condensation-prone environments.

About CO2 cylinders with siphon tubes

We offer CO2 cylinders with siphon tubes (expulsion tubes) installed for applications that require liquid CO2. Although there are various uses for siphon tubes, they are typically installed in larger tanks and can be used for refilling smaller CO2 cylinders.

Cylinders with a siphon tube installed are identified with the letters ‘ET’ stamped on the neck.

There are additional external components needed to complete transfer to a smaller tank. We don’t carry those parts, and we can’t confirm what items are necessary to complete the fill. Please make sure you have the correct parts, knowledge, and skill before attempting to fill any gas cylinder.

ISO versus DOT/TC cylinders

All cylinders must be manufactured and certified to a recognized standard. The US Department of Transportation (DOT), Transport Canada (TC), and UN/ISO all have established cylinder standards.

UN/ISO standards are newer than DOT/TC standards, and UN/ISO cylinders are equivalent to, and arguably superior to, DOT/TC-rated cylinders:

- UN/ISO is a universally recognized worldwide regulation for compressed gas cylinders, and UN/ISO cylinders are approved for use in almost every country around the world. UN/ISO cylinders can cross country borders and still be filled easily.

- UN/ISO service pressure is at or above the common fill pressure of a DOT cylinder with a +10% overfill designation. These higher capacities allow for UN/ISO cylinders to be easily integrated into a fleet of DOT/TC cylinders.

- UN/ISO cylinders contain friendly markings with service pressures rated in PSI and bar.

- UN/ISO cylinders remain in circulation at maximum capacity for the life of the tank. Due to the higher design ratings for pressure, UN/ISO cylinders do not require REE (Rejection Elastic Expansion) testing to achieve the common cylinder service pressures used and approved in North America. While REE is a valuable and stringent test, DOT/TC cylinders will often have their maximum fill pressure ratings reduced after testing.

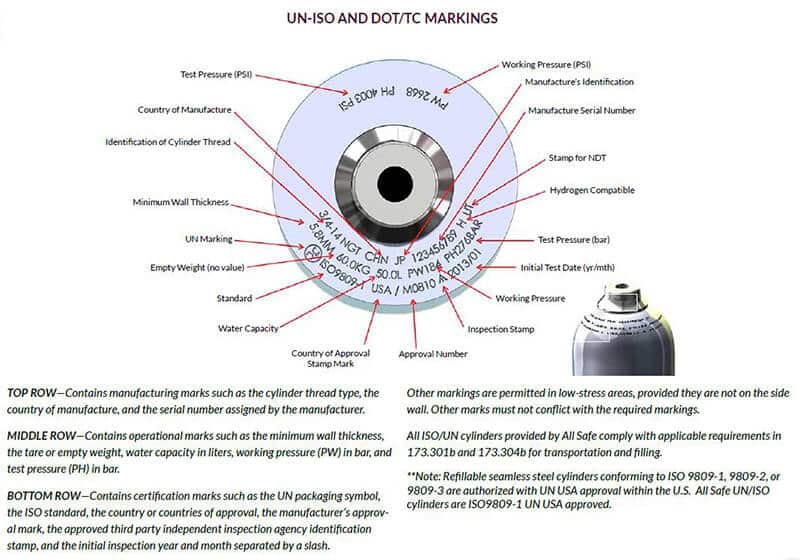

Facts and differences between UN/ISO and DOT/TC requirements

- Gas fillers in the USA can legally fill UN/ISO and DOT/TC cylinders that meet CFR regulations.

- UN/ISO and DOT/TC cylinders are manufactured in the U.S. and other foreign countries.

- DOT/TC and UN/ISO cylinders have the same dimensions, internal water volume, steel chemistry, and valve compatibility.

- UN/ISO cylinders have a higher working pressure and gas volume capacity than, DOT/TC cylinders.

- DOT/TC-stamped cylinders are acceptable for transport to, from, and within the U.S. UN/ISO-stamped cylinders must have “USA” country-of-approval marking to be acceptable for transport to, from, or within the U.S. Our UN/ISO cylinders are stamped “USA”.

- DOT/TC markings must conform to the applicable requirements of 49 CFR 178.35, and UN/ISO pressure receptacles markings must conform to the applicable requirements of 49 CFR 178.71.

- DOT/TC and UN/ISO cylinder markings are expressed in conventional units.

- DOT/TC date of manufacture is expressed as month-year (10-13), while UN/ISO is stamped year (4 digits) and month (2013/01)

- DOT/TC stamps service pressure only in PSI. UN/ISO cylinders have stamps for both service pressure (PW) and test pressure (PH) in bar and PSI.

- DOT/TC does not require inlet thread profile to be stamped. UN/ISO requires the inlet thread profile to be stamped.

- The manufacture approval number granted by U.S. Department of Transportation (Pipeline and Hazardous Materials Safety Administration) is required by both the DOT/TC and UN/ISO. If manufactured in same facility, the approval number will be the same.

- Third-party independent inspection is required for both DOT/TC and UN/ISO designs.

- There is no plus or star for UN/ISO cylinders. The service pressure is already at or above the 10% overfill authorized for select gas services by DOT/TC.

Choosing the Correct Valve for your Cylinder

There are a lot of different valves out there, and a lot of different cylinders and outlet sizes. We want to make sure you get the right valve the first time. Here are some things to know before you order a valve

- Gas Type. Naturally, the first thing to know is the gas your cylinder is designed to hold and that you intend to use. A valve for a different gas may fit your cylinder, but isn’t designed for the gas you’re using and won’t have the correct outlet fitting to connect to your regulator.

- Aluminum or Steel Cylinder. Valves seal to the cylinder differently depending on whether it’s made of steel or aluminum. Steel cylinders use NGT threads, and the compatible valves are tapered. They seal by using that taper to tighten securely to the steel threads. Aluminum (UNF) cylinders require a gentler sealing method, so compatible valves have straight (no taper) threads with a flat flange on top to seal against an O-ring on the cylinder top.

- Don’t Rely on a Ruler (because ¾” is not always ¾”). Measuring either the valve base or the cylinder inlet will not give you the correct size for the valve. For example, ¾” NGT valves measure about 1” from thread to thread. If you’re not a cylinder pro, the only way to know the size for certain is to ask your filler or compressed gas specialist to measure your cylinder and/or old valve for the correct size.

- The Numbers on the Valve Usually Don’t Tell the Story. Few valves are stamped with a plain-English version of the sizing. Most have proprietary identification marks that are unique to each manufacturer. Without a translation guide, they’re not much help in choosing a valve.

- Safety Matters. Your personal safety as well as the safety rating of the valve. The same size valve may come in multiple different safety pressure ratings. It’s crucial that you have the right safety for your cylinder size and material. Too low, and the safety will discharge too soon. Too high, and you can have an unintended discharge from the cylinder itself. Be sure to play it safe and know the correct safety rating before you order.

- PSI Calculation. To calculate the PSI needed for your valve, take the service pressure of your cylinder, multiply by 5, and then divide that by 3.

For example:

2265 (Cylinder Service Pressure) x 5 = 11,325

11,325 / 3 = 3775

The PSI for this valve would be 3775.

The bottom line is that unless you are certain of the size and safety rating you need, please seek professional assistance to determine the valve you need before you order. This will guarantee your safety and that you get the right valve the first time.