Oxygen Valves

Gas Cylinder Source supplies a full range of oxygen cylinder valves engineered for safe, compliant oxygen service across industrial welding and cutting, medical and dental care, laboratories, manufacturing, emergency response, and specialty gas applications. This category includes CGA-approved oxygen valves designed to provide precise flow control, secure regulator connections, and reliable pressure containment.

Explore Further (click here to read more):

All oxygen valves offered by Gas Cylinder Source are manufactured to Compressed Gas Association (CGA) standards and intended for installation on DOT-certified oxygen cylinders. Common configurations include CGA-540 industrial oxygen valves and CGA-870 medical oxygen post valves, each selected based on application, cylinder type, and regulatory requirements. These gas-specific outlet standards prevent cross-connection and ensure compatibility with the correct regulators and equipment.

Oxygen is a highly oxidizing gas, which makes valve design, materials, and cleanliness critical. Proper oxygen valve selection supports safe operation, regulatory compliance, and long-term equipment reliability. Gas Cylinder Source supports professionals who replace damaged valves, refurbish cylinders, or standardize oxygen systems across facilities and fleets.

All oxygen valves are intended for professional installation and service in accordance with DOT, CGA, OSHA, and applicable local regulations. Correct valve specification is essential to safe oxygen storage and use.

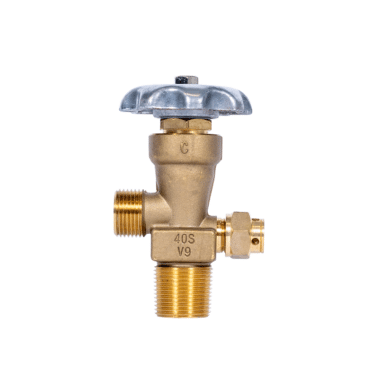

Sherwood leads the compressed gas industry with its CGA540 oxygen valve line. They’re the only valve to choose for welding and critical industrial oxygen uses.

Every oxygen valve from GCS features precise construction, innovative design, and tough testing. As a result, you get trusted Sherwood long-term performance and outstanding durability.

Gas Cylinder Source carries a wide selection of CGA540 oxygen valves. Valves are available for steel and aluminum nitrous tanks.

Oxygen Valve CGA540 3/4″ NGT .004″ Oversize – Sherwood

$39.70 – $40.20Price range: $39.70 through $40.20Oxygen Valve CGA540 3/4″ NGT .007″ Oversize – Sherwood

$17.20 – $19.70Price range: $17.20 through $19.70Oxygen Manifold Valve CGA540 1/2″ NGT – Sherwood

From $42.80Oxygen Valve CGA540 1/2″ NGT – Sherwood

From $39.60Oxygen Valve CGA540 1.125″ UNF – Sherwood

From $30.90Oxygen Valve CGA540 .750″ UNF – Sherwood

From $30.80Oxygen Valve CGA540 3/4″ NGT – Cavagna

$17.40 – $17.90Price range: $17.40 through $17.90FREQUENTLY ASKED QUESTIONS

▼ What are oxygen cylinder valves used for?

Oxygen cylinder valves control the release of oxygen gas from a cylinder and connect it to regulators or delivery equipment.

They serve as the primary interface between the pressurized oxygen inside the cylinder and downstream systems. Proper valve operation ensures safe and consistent oxygen flow.

These valves are designed specifically for oxygen service.

▼ Are oxygen valves gas-specific?

Yes, oxygen valves are gas-specific and must only be used for oxygen service.

Oxygen requires dedicated CGA valve standards to prevent incorrect connections and reduce fire risk. Using valves designed for other gases is unsafe and non-compliant.

Gas-specific valve design is a core requirement for industry safety.

▼ What CGA valve types are used for oxygen?

Oxygen cylinders commonly use CGA-540 or CGA-870 valves.

CGA-540 valves are typically used for industrial oxygen applications, while CGA-870 post valves are standard in medical and dental settings. Selection depends on the cylinder and intended use.

Matching the correct CGA valve ensures regulator compatibility and safe operation.

▼ Can an oxygen valve be replaced?

Yes, oxygen valves can be replaced if they are damaged, leaking, or out of specification.

Valve replacement must be performed by qualified personnel using approved procedures. Improper installation can compromise safety and oxygen delivery.

Replacement valves must meet CGA and DOT requirements for oxygen service.

▼ Are oxygen valves compatible with all oxygen cylinders?

Oxygen valves are compatible only with cylinders designed and labeled for oxygen service.

Thread type, pressure rating, and outlet configuration must match the cylinder specification. Compatibility is essential for safe and compliant operation.

Cylinder markings should always be verified before valve installation.

▼ Do oxygen valves require special cleanliness standards?

Yes, oxygen valves must meet strict cleanliness requirements.

Oxygen supports combustion, and contaminants such as oil or grease pose serious safety hazards. Oxygen valves are cleaned and prepared for oxygen service to minimize risk.

Cleanliness is critical in both industrial and medical oxygen systems.

▼ What pressure ratings do oxygen valves support?

Oxygen valves are rated to meet or exceed the service pressure of oxygen cylinders.

Most oxygen cylinders operate at 2,000-2,200 PSI. Valves must be designed to contain these pressures safely.

Pressure ratings are defined by valve design and manufacturer specifications.

▼ Are oxygen valves reusable?

Oxygen valves may be reused only if they remain within specification and pass inspection.

Valves exhibiting wear, contamination, or leakage should be replaced. Reuse decisions are commonly made during cylinder maintenance or recertification.

Safety considerations always take priority over reuse.

▼ How do I choose the correct oxygen valve?

Choosing the correct oxygen valve depends on cylinder type, CGA standard, pressure rating, and regulator compatibility.

The valve must be rated explicitly for oxygen service and match the intended application. Incorrect selection can lead to unsafe connections or filling refusal.

When uncertain, customers should consult their gas supplier or equipment manufacturer.

▼ Who should buy oxygen valves from Gas Cylinder Source?

Oxygen valves from Gas Cylinder Source are intended for use in welding shops, medical facilities, laboratories, manufacturers, and industrial service companies.

They are suitable for organizations that maintain oxygen cylinder fleets or refurbish equipment to ensure compliance.

Gas Cylinder Source supports both single-valve purchases and larger quantity orders for professional operations.